- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

What Makes ESD Mats Essential for Electronics Protection?

2025-09-05

In modern electronics manufacturing, static electricity poses a silent yet significant threat. A single electrostatic discharge (ESD) can damage sensitive electronic components, disrupt production efficiency, and increase operational costs. To combat this, ESD mats have become a fundamental part of static control strategies across industries such as electronics, semiconductors, telecommunications, and aerospace. But what makes ESD mats indispensable? How do they work, what types are available, and why should businesses invest in high-quality options?

What Is an ESD Mat and Why Is It Necessary?

An ESD mat is a specially designed surface covering that helps control electrostatic discharge by safely grounding electrical charges. These mats are essential wherever sensitive electronic components are handled or assembled because even minor static discharges — often undetectable by humans — can cause severe and irreversible damage.

The Threat of Electrostatic Discharge

Static electricity builds up naturally when two surfaces come into contact and then separate. In environments such as PCB assembly lines or semiconductor facilities, this buildup can result in:

-

Component damage: IC chips, transistors, and MOSFETs are highly sensitive to even minimal voltage spikes.

-

Data corruption: In storage devices, electrostatic discharges can cause partial or total data loss.

-

Reduced product lifespan: Damaged components often pass initial quality control but fail prematurely in the field.

-

Production downtime: ESD-related failures can halt entire assembly lines.

An ESD mat prevents these problems by continuously dissipating static charges and ensuring operators remain grounded while working.

Where ESD Mats Are Used

ESD mats are commonly used in:

-

Printed Circuit Board (PCB) assembly lines

-

Semiconductor manufacturing facilities

-

Electronic repair workshops

-

Cleanrooms and laboratories

-

Data centers and testing environments

Wherever precision electronics are handled, ESD mats are a crucial safeguard.

How Do ESD Mats Work and What Types Are Available?

Understanding how ESD mats function requires knowing their material structure and grounding mechanism.

How ESD Mats Function

ESD mats are designed to control static charges through two primary mechanisms:

-

Dissipative control

-

The mat’s surface allows static charges to flow slowly and safely to a ground point.

-

This avoids sudden discharges, protecting delicate components.

-

-

Conductive grounding

-

Conductive layers inside the mat channel electricity directly into the grounding system.

-

Operators connect themselves via wrist straps, ensuring they are grounded at the same potential as the mat and the work surface.

-

Common Types of ESD Mats

| Type | Surface Resistance | Applications | Advantages |

|---|---|---|---|

| Dissipative Mats | 10⁶ Ω to 10⁹ Ω | Assembly lines, workbenches | Safe charge dissipation, operator-friendly |

| Conductive Mats | 10³ Ω to 10⁶ Ω | High-risk static areas | Fast grounding, ideal for heavy-duty use |

| Dual-Layer Mats | Combines both | Electronics manufacturing labs | Balance between speed and safety |

| Vinyl ESD Mats | Varies | Standard workstations | Durable, chemical-resistant |

| Rubber ESD Mats | Varies | Soldering and heat-prone areas | Heat-resistant, long lifespan |

Selecting the right type depends on the working environment, sensitivity of the components, and safety requirements.

Technical Specifications and Product Parameters

When selecting an ESD mat, understanding its technical specifications is critical to ensuring optimal performance. High-quality mats from Xinlida are manufactured to meet strict industry standards.

3.1 Product Parameters

| Parameter | Specification |

|---|---|

| Material Composition | Premium static-dissipative rubber or vinyl |

| Surface Resistance | 10⁶ Ω to 10⁹ Ω (dissipative layer) |

| Bottom Layer Resistance | 10³ Ω to 10⁵ Ω (conductive layer) |

| Thickness | 2mm / 3mm / 5mm |

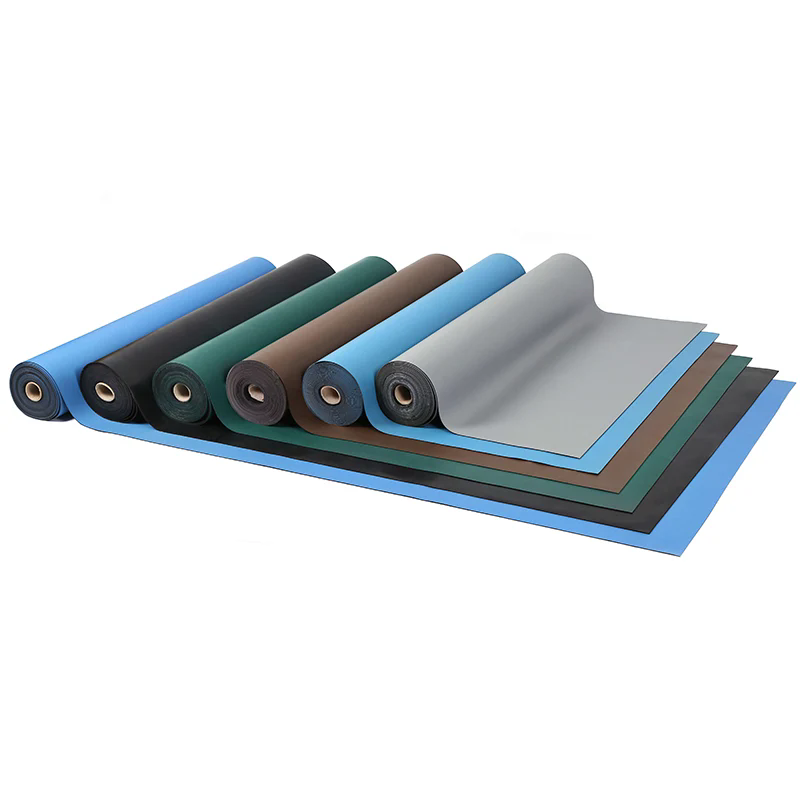

| Color Options | Green, Blue, Grey, Black |

| Temperature Resistance | Up to 120°C for rubber-based mats |

| Chemical Resistance | Resistant to flux, solder, and cleaning agents |

| Standards Compliance | ANSI/ESD S20.20, IEC 61340-5-1 |

Installation and Usage Best Practices

-

Proper Grounding: Always connect mats to a reliable earth grounding point.

-

Regular Testing: Use an ESD tester to verify surface resistance periodically.

-

Operator Grounding: Combine mats with ESD wrist straps for maximum protection.

-

Surface Cleaning: Clean mats with approved ESD-safe solutions to maintain performance.

By following these practices, businesses can ensure the mats deliver consistent protection and extend their lifespan.

Why Choose High-Quality ESD Mats from Xinlida

Investing in premium-quality ESD mats is not just a safety measure — it’s a cost-saving strategy. Inferior mats often degrade quickly, fail to meet resistance specifications, and may expose sensitive electronics to damage.

Key Advantages of Xinlida ESD Mats

-

Precision Engineering: Manufactured with advanced technology for stable surface resistance.

-

Durable Materials: Long-lasting rubber and vinyl composites withstand heavy industrial use.

-

Compliance Guaranteed: Meets international ESD safety standards.

-

Customization Options: Available in multiple sizes, colors, and thicknesses to suit your workspace.

Xinlida’s ESD mats are trusted by global electronics manufacturers, research labs, and repair facilities for their reliability and performance.

Frequently Asked Questions (FAQs)

Q1: How do I know if my ESD mat is working correctly?

Answer: You can test your ESD mat using an ESD resistance tester. If the surface resistance falls within the recommended range (typically between 10⁶ Ω and 10⁹ Ω for dissipative mats), the mat is functioning properly. Regular testing ensures ongoing protection.

Q2: Can I use an ESD mat without grounding it?

Answer: No. Without grounding, an ESD mat cannot safely dissipate static charges, making it ineffective. Always connect your mat to a proper ground point, and combine it with operator grounding devices such as wrist straps for comprehensive protection.

Electrostatic discharge may be invisible, but its effects on sensitive electronics are costly and disruptive. Choosing the right ESD mat — one that meets strict resistance specifications and complies with international standards — is essential for maintaining product quality and operational efficiency.

Xinlida offers a complete range of high-quality ESD mats engineered for performance, safety, and durability. Whether you operate a large-scale electronics factory, a research laboratory, or a small repair workshop, Xinlida provides tailored solutions to protect your investments.

For more information about our full range of ESD protection products, contact us today and let Xinlida help you build a safer, static-free workspace.