- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

Why Are ESD Mats Critical for Workplace Safety?

2025-09-26

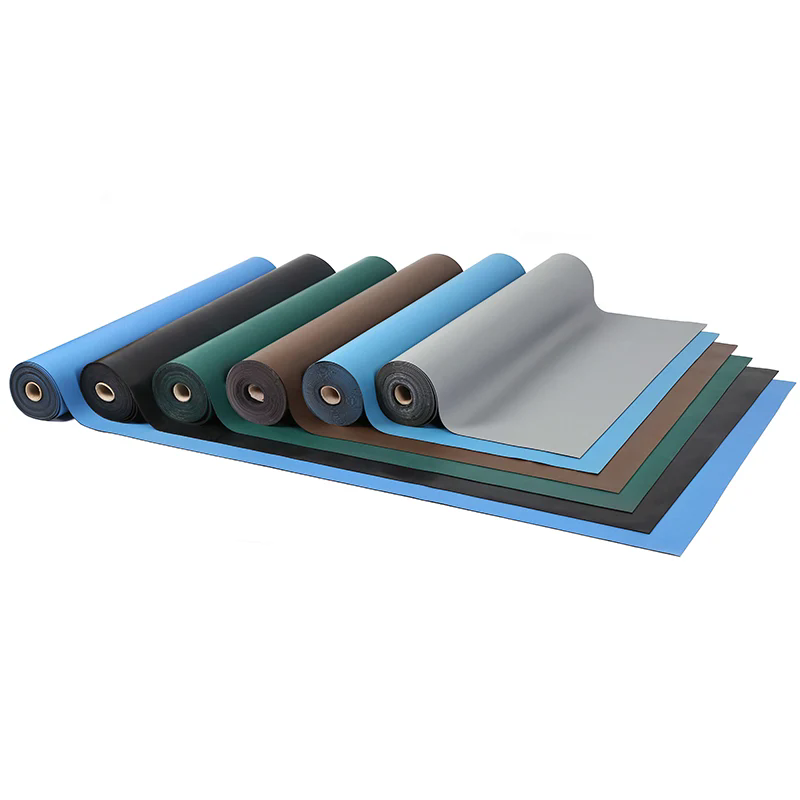

Electrostatic discharge (ESD) is one of the most underestimated risks in modern workplaces. From assembly lines to cleanrooms, the silent transfer of static electricity can cause irreversible damage to sensitive components. An ESD mat is a protective surface designed to dissipate static charges, ensuring a safe and controlled environment.

An ESD mat provides:

-

A controlled path for static charges to safely flow to ground.

-

A protective buffer against environmental static buildup.

-

A safer working surface for both personnel and devices.

The importance of ESD control is highlighted in international standards such as ANSI/ESD S20.20, ISO, and IEC guidelines. These require organizations to implement static-safe materials like mats, wrist straps, and grounding points. Therefore, choosing the right ESD mat is not optional but essential for compliance, safety, and long-term operational efficiency.

How Does an ESD Mat Work and What Technical Parameters Should You Look For?

To understand the effectiveness of ESD mats, we must first ask: how do they work? At their core, ESD mats are engineered from conductive or dissipative materials. When a charged object touches the mat, the material absorbs and neutralizes the charge, directing it safely to ground through a grounding cord. This prevents harmful discharges from reaching delicate electronics.

However, not all ESD mats are built the same. Selecting the right product depends on a balance of technical parameters, materials, and workplace application. Below is a summary of common parameters that professionals consider when evaluating an ESD mat:

| Parameter | Description | Standard Range / Value |

|---|---|---|

| Surface Resistance | Ability of the mat surface to resist electrical current. | 10⁶ – 10⁹ ohms (dissipative), <10⁶ (conductive) |

| Material Composition | PVC, rubber, or vinyl with carbon-loaded layers for conductivity. | Multi-layer construction preferred |

| Thickness | Impacts durability and comfort. | 2mm, 3mm, or 4mm options available |

| Color Options | Typically green, blue, or gray for workplace compliance and contrast. | UV-stable, fade-resistant pigments |

| Temperature Resistance | Ability to withstand soldering heat and environmental variations. | -20°C to +80°C |

| Cleaning Requirements | Ease of maintenance without degrading ESD properties. | Compatible with mild detergents, alcohol |

| Grounding Method | One or more grounding snaps for cords and wrist straps. | 10mm universal snap |

Why these specifications matter:

-

Surface resistance defines whether the mat will properly dissipate charges without being too conductive.

-

Material quality determines longevity; rubber-based mats resist chemicals and solder better than vinyl.

-

Thickness affects both ergonomics (comfort for long working hours) and durability under heavy equipment.

Thus, selecting an ESD mat is more than picking a color or size—it’s about aligning product parameters with safety standards and operational needs.

Why Should Companies Invest in ESD Mats Instead of Alternative Solutions?

Some managers may ask: why not just rely on grounding wrist straps or anti-static sprays? While these solutions play a role, they are incomplete without mats.

Here’s why:

-

Wrist straps only protect the worker, not the devices or surfaces. An ESD mat ensures tools and parts also remain static-free.

-

Sprays provide temporary static reduction but degrade quickly and require constant reapplication.

-

Floor mats alone may not cover workbenches, where the most sensitive assembly tasks occur.

Investing in a high-quality ESD mat delivers long-term cost savings:

-

Reduced product failures – each avoided electrostatic event prevents costly repairs or replacements.

-

Compliance with audits – industries such as electronics manufacturing require documented ESD controls.

-

Worker confidence – employees are more efficient when they trust their workstation is safe for handling precision devices.

In competitive industries, reputation is built on reliability. One defective batch caused by static discharge can damage trust with clients permanently. That’s why organizations worldwide rely on ESD mats as a cornerstone of their electrostatic protection system.

How to Choose and Maintain the Right ESD Mat for Your Workplace

Selecting the right ESD mat involves how you plan to use it and why ongoing maintenance matters.

Key Considerations for Choosing:

-

Work Surface vs. Floor Application: Bench mats are thinner and optimized for assembly work, while floor mats provide ergonomic comfort for standing operators.

-

Single-layer vs. Multi-layer: Multi-layer mats with conductive cores offer longer lifespan and improved charge dissipation.

-

Grounding Requirements: Ensure the mat includes snaps or cords that integrate seamlessly with your facility’s grounding system.

-

Size and Customization: Mats can be supplied in rolls or pre-cut sizes to fit benches, carts, or entire production lines.

Maintenance Best Practices:

-

Clean mats weekly with approved ESD cleaners to preserve resistance values.

-

Test surface resistance regularly using an ESD tester to ensure compliance.

-

Replace mats that show visible wear, burns, or permanent staining.

Common Mistakes to Avoid:

-

Using standard household cleaners, which can leave residues that increase surface resistance.

-

Overlooking grounding connections—an ungrounded ESD mat is no better than a regular surface.

-

Ignoring periodic resistance testing, which is required in most compliance programs.

By adopting these practices, companies can extend the lifespan of their mats and guarantee consistent ESD protection.

Frequently Asked Questions About ESD Mats

Q1: How do I know if my ESD mat is still effective?

A: Regular resistance testing with an ESD meter is the best way to confirm. If results fall outside the 10⁶ – 10⁹ ohm range for dissipative mats, replacement is necessary.

Q2: Why do ESD mats have different colors?

A: Color has no impact on performance. Instead, it helps in workplace organization, visibility of components, and compliance with cleanroom requirements.

Q3: Can I use an ESD mat without grounding cords?

A: No. An ESD mat must be properly grounded to function. Without grounding, the mat simply stores charges instead of dissipating them.

The role of ESD mats in modern workplaces cannot be overstated. They are not merely accessories but essential safeguards that protect products, employees, and reputations. By asking why ESD mats are necessary and how they truly work, organizations gain the clarity needed to implement lasting electrostatic safety programs.

For businesses seeking durable, compliant, and customizable solutions, Xinlida has established itself as a trusted manufacturer in the field. With a strong commitment to product quality and customer satisfaction, Xinlida offers ESD mats engineered to meet global standards while supporting long-term operational reliability.

If you are considering upgrading your workplace safety measures, we invite you to contact us today for tailored solutions that align with your industry’s needs.