- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

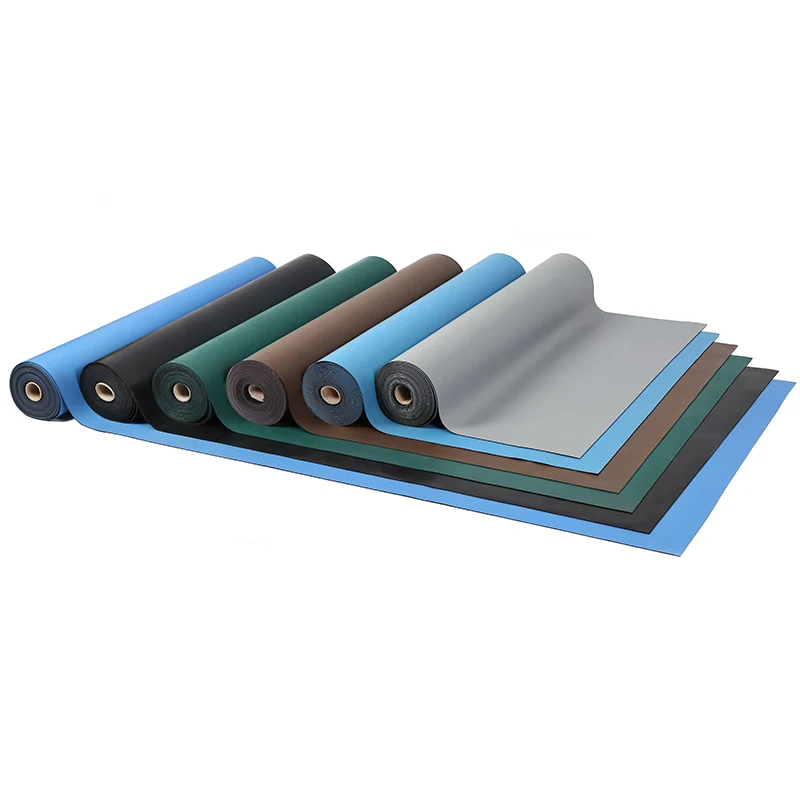

Why Your ESD Mat's Specs Are Non-Negotiable?

An ESD mat is not a passive table cover. It is an active, engineered component of your grounding system. Its mission is to create a dissipative pathway, safely bleeding off static charges from tools, components, and operators to a common ground point. This prevents a sudden, damaging discharge that can destroy a sensitive microchip instantly or weaken it, causing a latent failure that manifests weeks or months later.

The performance of this crucial task is quantified in its specifications. Ignoring these specs is akin to ignoring the load rating of a crane. Here are the core parameters that separate professional-grade protection from amateur hour.

Critical Performance Characteristics:

-

Electrical Resistance (Surface & Volume): The cornerstone of ESD protection. This defines the mat's ability to control the flow of electricity.

-

Charge Decay Time: A dynamic measure of how quickly a mat can neutralize a static charge. Speed is safety.

-

Material Integrity: The mat must withstand its environment without sacrificing its electrical properties.

-

Durability & Safety: Features that ensure long-term value and workplace safety.

To provide absolute clarity, the following table outlines the standard specifications for a high-performance Vinyl ESD Mat, a workhorse solution for most bench applications.

Professional ESD Mat Specification Table

| Parameter | Test Method | Ideal Specification | The Real-World Impact |

|---|---|---|---|

| Surface Resistance | ANSI/ESD S4.1 | 10^6 to 10^9 ohms | This "sweet spot" is conductive enough to ground charges safely, but resistive enough to prevent a dangerous rapid discharge. |

| Volume Resistance | ANSI/ESD S4.1 | 10^6 to 10^9 ohms | Ensures consistent performance throughout the mat's entire thickness, not just on the surface. |

| Charge Decay Time | ANSI/ESD S4.1 | < 0.05 seconds | A superior mat will dissipate a 5000V charge to zero in milliseconds, far exceeding the minimum standards. |

| Fire Resistance Rating | UL 94 | HB | The material will stop burning on its own, a critical safety feature for any workplace. |

| Operating Temperature | - | -12°C to 60°C (10°F to 140°F) | Guarantees performance stability across a wide range of industrial environments. |

| Standard Thickness | - | 2mm (0.08") | Offers optimal cushioning and durability. 3mm is available for heavy-duty use with sharp tools. |

Features Beyond the Numbers

A list of specs is meaningless if the product fails under daily use. The best ESD mats are designed with the end-user in mind. At Dongguan Xin Lida Anti-Static Products Co., Ltd., we engineer our mats with these critical features:

-

Multi-Layer Construction: A common design bonds a dissipative top layer to a conductive bottom layer. This architecture ensures charges are collected on the surface and efficiently channeled to the ground snaps.

-

Chemical & Abrasion Resistance: The surface must resist degradation from common solvents, oils, and repeated friction to maintain its electrical and functional integrity over years of use.

-

Anti-Glare, Low-Shedding Surface: A slight texture reduces eye strain for technicians and prevents tiny component "walking." The surface should not shed particles that could contaminate clean areas.

-

Integrated Grounding System: The mat should be ready for immediate integration into your EPA with standard, durable snap fittings for a reliable connection.

ESD Mat FAQ

1. What are we doing wrong?

Cleaning is essential, but the wrong technique is worse than not cleaning at all. Using conventional cleaners, isopropyl alcohol with high impurity levels, or abrasive wipes can deposit insulating films or physically damage the dissipative surface. This permanently alters the mat's resistance. Always use a dedicated ESD mat cleaner, which is specifically formulated to lift soil without leaving a residue. Apply the cleaner with a soft, non-abrasive cloth. Your mat's performance depends on this simple maintenance step.

2. Is there a tangible Return on Investment (ROI) from purchasing a premium ESD mat versus a generic one?

Absolutely. The ROI is calculated in reduced failure rates. A generic, non-compliant mat might cost 20% less upfront. However, if it causes just one field failure of a $500 assembled PCB, you've already lost the entire cost savings. Premium mats, like those from Dongguan Xin Lida Anti-Static Products Co., Ltd., offer verified and consistent performance, longer lifespan, and better durability. This directly translates to fewer scrapped components, lower repair costs, enhanced product reliability, and protected brand reputation. The initial cost is dwarfed by the value of prevention.

3. Is this sufficient grounding, or do we need to ground the mat itself?

This is a common and dangerous misconception. The mat itself MUST be independently grounded. A wrist strap only grounds the operator. If the mat is not grounded, any charged object (a tool, a component brought from another area) placed on the mat will have no safe path to earth. The charge will stay localized, creating a potential difference that can easily arc to a sensitive component. Your grounding system is a chain: Common Point Ground > Ground Cord > Mat and Wrist Strap. Every link is vital.

Secure Your Production Line with Certified Protection

In the high-stakes world of electronics, hope is not a strategy. You cannot "hope" your ESD mat is working. You need verified, quantifiable, and reliable protection. The integrity of your products depends on the quality of every component in your EPA, starting with the work surface.

Stop gambling with static. Choose a partner who understands the critical nature of your work. For over 20 years, Dongguan Xin Lida Anti-Static Products Co., Ltd. has been a trusted source for high-performance anti-static solutions, providing the industry with the confidence that comes from superior materials and rigorous manufacturing standards.

Don't let a weak link compromise your quality. Contact Dongguan Xin Lida Anti-Static Products Co., Ltd. today to request technical data sheets, samples, and consult with our specialists. Ensure your ESD mats are part of the solution, not the problem.